One of the earliest forms of environmental contamination is metal mining. This process dates back to prehistoric times, and researchers estimate that large-scale metal mining has existed for approximately 7,000 years. Since then, mining operations have only scaled, leading to serious environmental concerns.

The mining process releases various toxic metals, such as arsenic and lead, into surrounding bodies of water and soil. These pollutants contaminate the environment, directly impacting the health and safety of people and animals. According to research from 2023, at least 23 million people globally live on floodplains that contain metal-mining pollution.

With climate change promoting more frequent severe weather events, the environmental impacts of heavy metal mining may soon become even more widespread. Fortunately, mining companies can take action. Learn about the dangers of heavy metal contamination and how businesses can improve safety and compliance.

Common Heavy Metals and Their Environmental Impacts

Much of the waste produced during ore extraction is contaminated with toxic metals. Once processed and left behind in mine pits and rock piles, it’s exposed to the environment. Since waste piles can span hundreds of acres, the effects of heavy metal contamination can be immediate and widespread. Additionally, dust emissions, acid mine drainage, fossil fuel usage, and seasonal variations in precipitation and temperature all contribute to contamination.

Heavy metal pollution from mining can stem from the following:

- Arsenic is commonly found in gold, lead and copper ores and is released during processing, smelting and tailings disposal. This heavy metal can contaminate ground and surface water, disrupting ecosystems and causing severe health effects through long-term exposure.

- Cadmium is a by-product of zinc, lead and copper mining. It’s often present in mining waste, including rock and tailings. When it accumulates in the environment, cadmium can kill plants and severely impact the health of animals and humans.

- Chromium is present in chromite ore mining and processing, as well as some nickel and platinum mining. Hexavalent chromium is toxic and carcinogenic, and chronic exposure in the environment can have health and safety implications.

- Copper is released during copper ore extraction and processing. At high concentrations, it’s particularly toxic to aquatic life, disrupting food chains and bioaccumulating in fish and other living organisms.

- Lead is typically found in lead, zinc and silver ores. It’s released during processing and smelting, contaminating water and soil and harming wildlife and humans as a neurotoxin.

- Mercury is often found in gold mining and cinnabar processing. Mining waste can release mercury directly into the atmosphere because it evaporates at a low temperature. The mercury can then leach into water and soil miles away, becoming highly toxic to humans and wildlife.

- Nickel is present in nickel, copper and platinum group metal mining. When released into the environment in high concentrations, it creates toxic aquatic ecosystems and can cause allergic reactions and respiratory issues in humans.

- Zinc is released during zinc, lead and copper mining and ore processing. This heavy metal disrupts ecosystems and is highly toxic to aquatic wildlife.

Assessing Heavy Metal Pollution From Mining in Wastewater

Mining companies must be extremely diligent in mitigating human health risks, protecting wildlife habitats and following strict government mining regulations. The first step in heavy metal remediation is identifying and quantifying heavy metal pollutants. Since water is one of the most contaminated sources, wastewater should be a central focus.

Start by implementing a sampling and monitoring process. Select specific locations, such as process water discharge points, tailings ponds and runoff areas, where teams can collect samples at regular, established intervals. Once the samples are collected, companies can analyze them for heavy metals:

- Atomic absorption spectroscopy is highly sensitive for metals like lead, cadmium and arsenic.

- Inductively coupled plasma mass spectrometry detects multiple metals at trace levels simultaneously.

- X-ray fluorescence is useful for rapid, on-site screening.

During analysis, teams should examine wastewater for concentrations of priority metals, particularly the ones most often found in and released by mining activities. Additionally, they can look for pH and redox potential, which influence metal solubility and mobility, and assess total suspended solids, as metals can bind to particles.

The assessment should follow relevant mining environmental compliance regulations, such as 40 CFR Part 136, 40 CFR Part 122 and 40 CFR Part 440 of the Clean Water Act (CWA). Once heavy metal data is collected, teams can create trend analyses and risk assessments to inform treatment methods. Recordkeeping and reporting must also follow CWA guidance.

Treatment Methods for Heavy Metal Remediation

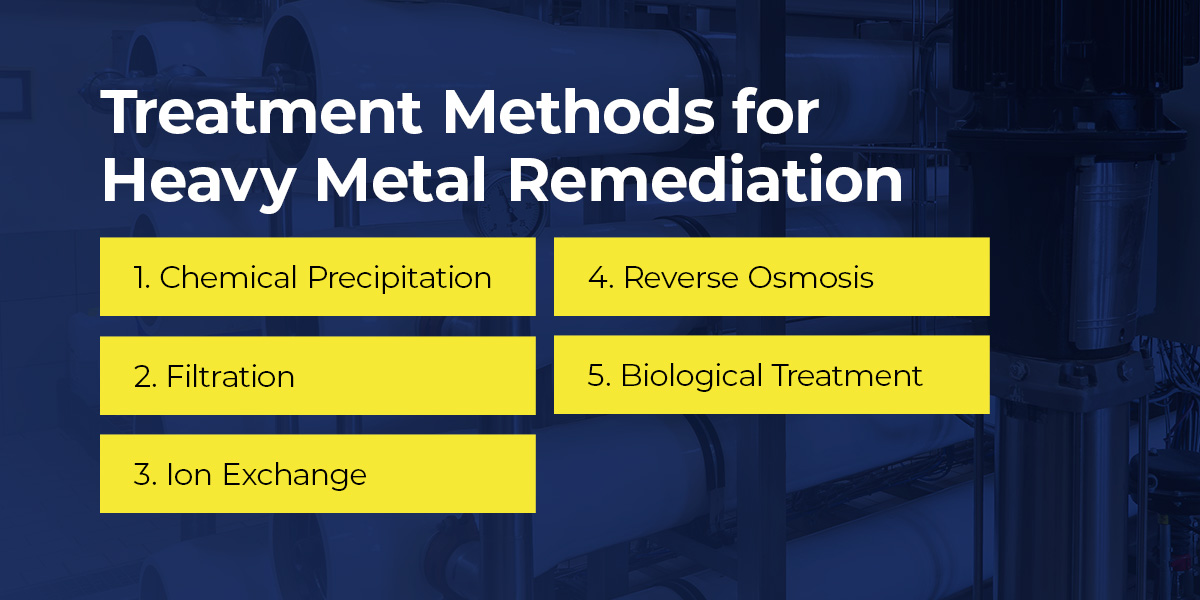

Common strategies for avoiding wastewater contamination in mining include chemical precipitation, filtration, ion exchange, reverse osmosis, and biological treatment. Some more basic techniques are continually improving using new technology. While traditional approaches can still be effective, they have certain downsides.

1. Chemical Precipitation

In chemical precipitation, chemicals such as lime or sulfides are introduced to wastewater, causing dissolved metals to form solid particles, or precipitates, that can be separated. Some advanced approaches include selective or sequential precipitation, where different chemicals are added in stages to target specific metals. Electrochemical precipitation can enhance removal efficiency and reduce chemical usage.

Advantages:

- Effective for removing a wide range of heavy metals

- Relatively low capital cost

Considerations:

- Generates large volumes of sludge requiring disposal

- May not achieve very low contaminant levels

- Ongoing chemical costs

2. Filtration

During mineral contaminant filtration, wastewater passes through filters, such as sand, membranes or cartridges, to physically remove suspended solids and some metal particulates. Using ultrafiltration and nanofiltration membranes can remove smaller particles and certain dissolved metals. Additionally, hybrid systems can combine filtration with adsorption or advanced oxidation processes for improved contaminant removal.

Advantages:

- Simple operation

- Effective for removing particulates and some metals

- Can be combined with other treatments for better results

Considerations:

- Filter media require regular replacement or cleaning

- Less effective for dissolved metals

3. Ion Exchange

This process directs wastewater through adsorption mechanisms, membrane filters or other methods to trap metals for later removal. More advanced ion exchange systems use engineered resins with higher metal selectivity, continuous ion exchange processes or membrane technologies to improve performance and reduce fouling.

Advantages:

- Highly selective for specific metals

- Can achieve low discharge limits

- Regenerable resins reduce waste

Considerations:

- More complex and expensive

- Sensitive to fouling by suspended solids or organics

4. Reverse Osmosis

In reverse osmosis, water is pushed through a semipermeable membrane under pressure. This process separates out dissolved metals and other contaminants. Some reverse osmosis systems incorporate pretreatment steps, such as advanced oxidation or anti-fouling coatings on membranes, and multi-stage or hybrid membrane processes for contaminant removal.

Advantages:

- Removes various contaminants, including dissolved metals

- Produces high-quality effluent suitable for reuse

Considerations:

- High energy consumption and maintenance costs

- Generates concentrated brine that requires further handling

5. Biological Treatment

Typically used in constructed wetlands or bioreactors, biological treatment uses microorganisms or plants to absorb, transform or immobilize heavy metals in wastewater. More advanced biological methods include genetically engineered microbes for improved metal uptake and bioelectrochemical systems. These treatments may also use sequential anaerobic-aerobic bioreactors to treat complex waste streams.

Advantages:

- Can be cost-effective for certain metals and large flows

- Environmentally friendly due to minimal chemical use

Considerations:

- Slower process

- Sensitive to changes in water chemistry

- Not effective for all heavy metals or at high concentrations

Implementing Wash Racks for Heavy Metal Removal

Companies can adopt additional techniques to better protect the environment and meet regulatory compliance. Specialized wash stations clean vehicles and machinery, capturing and treating wash water to remove heavy metals before it enters the main wastewater stream.

Equipment wash racks prevent heavy metals from entering wastewater at the source. They reduce the overall contaminant load and support compliance by minimizing spillage from vehicles and machinery. Additionally, equipment washing can be integrated with water recycling for operational efficiency.

Choose ESD Waste2Water for Mining Wastewater Treatment

Implementing mining wastewater treatment methods is a crucial and necessary step. While mining companies must legally remediate heavy metal contamination, it’s also essential for preserving human and wildlife health and safety. One of the best ways to support treatment efforts while saving water in a closed-loop system is by using wash racks for mining equipment.

ESD Waste2Water has extensive experience providing effective wastewater management systems for companies across industries, including mining. Cleaning equipment and vehicles correctly removes and contains contaminant buildup, which is then biologically treated and refined so the water can be reused. This process also minimizes harmful spillage.

Congruent to biologically treating the wash water, the closed loop system can be used in conjunction with a Dual Path Auger System that empties the heavy material into a fork liftable hopper or Solids Bunker for dewatering and easy dumping. The customizable system can come as an ESD Portable Containment Island Auger Pad or an embedded system. Operators can focus on production while staying compliant to EPA requirements due to the elimination of manual labor or pits.

With mining equipment washing, companies can take a meaningful step toward compliant contamination mitigation, especially when combined with other strategies. Learn more about ESD’s wash rack systems, and reach out today to get started.