Mining operations have always faced concerns regarding their impact on the environment, whether that’s due to energy consumption, chemical use or greenhouse gas emissions. Fortunately, achieving sustainability in the mining industry is becoming increasingly viable thanks to the advancements in technology. These technologies are applicable whether you aim to try alternative processes, improve your machines, or provide better safety for your workers and surroundings. This article lists the top seven systems you can implement.

7 Systems for Environmentally Friendly Mining Operations

Here are the best sustainable mining practices that have been adopted worldwide:

1. Water Management

Sustainable water management involves recycling and treating wastewater with the help of closed-loop and filtration systems. This conserves freshwater resources by controlling the quantity of water used. The mining industry can easily use a lot of water resources. With a closed-loop system, you can reclaim your used water, whether that’s for separating minerals or washing your machinery.

One way to do this is to adopt closed-loop wash racks that use high-pressure systems to clean your equipment. With a wash rack, dirty water and mud run down the drain and separate. Grease and oil are also biologically treated and refined. The treated water is looped back into the system to be reused, with no contaminants going into the streams and rivers.

Managing wastewater sustainably also helps you save time and money in the long run and comply with EPA regulations.

2. Renewable Energy

Renewable energy sources help reduce reliance on coal power, cutting down carbon emissions. Coal mining is hazardous, and methane gas can easily explode. Using renewable energy helps avoid these risks. Multiple mining sites have already adopted renewable energy sources as one of their green mining solutions.

Your company can choose to adopt solar, wind and hydropower, especially if you’re located in sunny or windy regions. Additionally, you can work with electric- or natural-gas-powered equipment, which reduces carbon and noise emissions from internal combustion engines.

3. Advanced Carbon Capture and Storage

Advanced carbon capture and storage (CCS) was designed to reduce carbon dioxide emissions from industrial facilities to help achieve net-zero emissions. This technology captures the emissions before they reach the atmosphere to store them underground. Some researchers propose using solar power to capture and store carbon. You can also identify opportunities by accelerating processes like mineralization.

Stored carbon emissions are transferred by ship, pipeline, rail or truck. These are injected into deep geological formations like depleted oil and gas reservoirs or used in other applications.

4. Waste Management

Mining activities produce large amounts of waste, up to 65 billion tons per year. To reduce environmental risks, find a method of recycling and waste treatment. Proper waste management is required to comply with the many environmental laws, including the Resource Conservation and Recovery Act and the Toxic Substances Control Act.

Waste management strategies cater to the various wastes, such as mill tailings and waste rocks. For example, you can use waste rocks for construction purposes and reprocess tailings to extract unused minerals.

5. Technological Innovations

Technology plays a role in multiple steps of the mining process. Here are examples of some applications:

- Techniques like precision drilling improve accuracy and significantly reduce mining waste.

- Autonomous mining equipment enhances efficiency and can reduce the need for human intervention in risky areas, improving worker safety.

- Electric-powered trucks, excavators and loaders are considered eco-friendly mining equipment as they produce zero tailpipe emissions, improving air quality.

- Technologies or software that enhance monitoring and communication help improve emergency responses.

6. Lower-Impact Mining Methods

Companies can also adopt lower-impact methods for more eco-friendly mining practices. These methods include:

- Selective ore mining: This process aims to mine the best ores, leaving the low-grade variety behind. It’s a great way to reduce mining waste and is ideal for areas with large, valuable deposits.

- Solution mining: Solution mining dissolves minerals through water or brine, with the resulting solution being pumped to the surface. This process is low impact as it produces no waste rock or tailings and has little surface disturbance.

- In-situ bioleaching: In-situ bioleaching involves direct bioleaching in the tailings pond or orebody, avoiding mining entirely. It’s used with ores that are difficult to mine, such as those in abandoned mine pits.

7. Land Rehabilitation

Traditional mining processes usually result in land degradation, making postmining processes significant in sustainability. One study found that used paste backfilling from tailings, cement and water can be used to backfill open stopes, stabilizing the surface and restoring the natural landscape. Reforestation projects and working closely with the surrounding communities can also help restore the environment to its good health.

Why the Mining Industry Needs More Sustainable Practices

Many researchers are trying to identify how to make mining sustainable, considering the industry’s significant impact on the world. Albeit impactful, mining operations disrupt the natural environment. Disregarding sustainable mining methods can lead to a loss of biodiversity, contribute to climate change and make you unknowingly break regulations aimed at preservation.

Green mining or sustainable mining involves practices that protect the nearby surroundings, are economically viable and socially responsible. Many mining companies have started adopting eco-friendly mining techniques to help reduce the problem.

Frequently Asked Questions

To further understand how you can adopt sustainable mining practices, consider these questions:

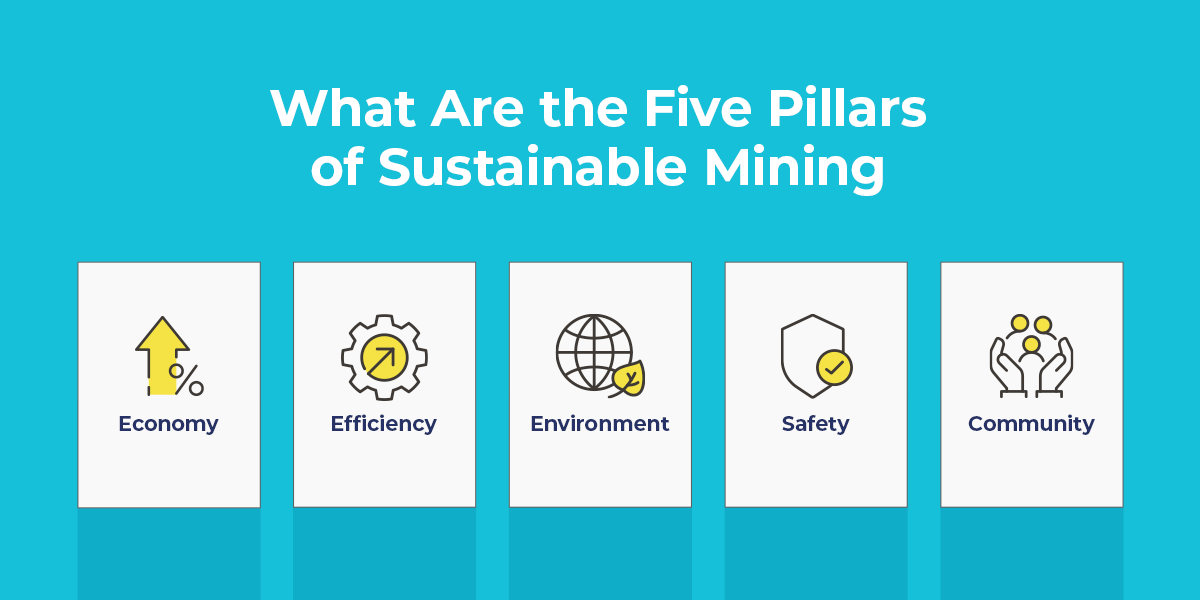

What Are the Five Pillars of Sustainable Mining?

The five pillars of sustainable mining include:

- Economy: This involves ensuring that eco-friendly practices are sustainable in the long run and do not sacrifice the mine’s profits. Economic operations benefit all stakeholders, including employees and local communities.

- Efficiency: The resources need to be managed efficiently so as not to lead to production problems.

- Environment: The sustainable practices are meant to enact environmental values. Without the proper steps, there could be long-term liabilities.

- Safety: Every mining company should prioritize the workers’ safety, including adopting proper and accurate reporting systems and providing sufficient training.

- Community: The community needs to support the mining operation, or oppositions and confrontations may arise. Mining companies may choose to hire locals to increase this support.

How Can We Make Mining More Efficient?

Adopting suitable sustainable practices can make mining more efficient. Because water management reduces the need for more freshwater, it offers a more sustainable and resourceful way of cleaning and maintaining your equipment. Recycling internally can also help you reuse items, such as used oil or spilled diesel, instead of purchasing them brand-new. Some practices may not be practical for your use case, so you should choose strategically.

Which Method of Mining Is the Most Sustainable?

The most sustainable mining method caters to the five pillars and is practical for your mining operations. For instance, if you need to mine ores in hard-to-reach locations, in-situ bioleaching might make the most sense. You can also adopt multiple sustainable practices in other areas, such as water management, waste management and land rehabilitation.

ESD Waste2Water Can Help You Adopt Sustainable Practices

ESD Waste2Water can help you reduce your use of freshwater resources and heavy material manual labor. Our closed-loop wash racks and heavy duty above ground portable wash pads allow you to wash your equipment and vehicles, such as crushers, loaders, drill rigs and dozers, and reclaim used water.

ESD can assist designing a wash rack or provide heavy duty above ground wash pads with wash water recycling systems, water cannons and an optional auger system for material handling. ESD’s Patent Pending Auger System comes as a Single Path Embed or an Above Ground Dual Path Containment Island Wash Pad. The Auger System is designed to eliminate manual material handling by transporting it via a screw auger to a mud bunker or solids handling hopper. This system helps you stay compliant with the EPA Clean Water Act regulations while saving your business money over time. Contact us today to learn more about our services!