Why Is Polypropylene Used For Fire Truck Tanks

Firetruck tanks can contain one of several different materials — polypropylene, fiberglass, steel and stainless steel. But polypropylene, a strong, lightweight plastic, offers several distinct advantages.

- Corrosion resistance: Polypropylene is not a metal, so it resists corrosion exceptionally well.

- Light weight: Polypropylene is much lighter than steel — and significantly lighter than fiberglass as well. So trucks carrying polypropylene tanks rather than metal tanks save money because the lighter weight causes them to consume less fuel. A lighter truck is also much easier to handle on the road. For these reasons, polypropylene tanks are exceptionally beneficial on different types of fire trucks.

- Leakproof extrusion welding: One benefit of fiberglass tanks over polypropylene tanks is that they are molded into one complete piece, so they have no seams where water can leak out. But polypropylene’s extrusion welding offers leakproof seams that can hold in huge volumes of water. Extrusion welding is a type of welding used to shape and build thermoplastic structures, such as polypropylene tanks. It uses a welding apparatus that has a nozzle for hot air and an extruder to push malleable material — such as the thermoplastic — into place. With high-quality materials and craftsmanship, leakage shouldn’t be an issue.

- High impact resistant material: Any damage to a poly tank can be very localized at an impact zone thus helping maintain the integrity of the tank overall. This attribute can keep repair to a minimum in both time and material.

How The Tanks Are Manufactured

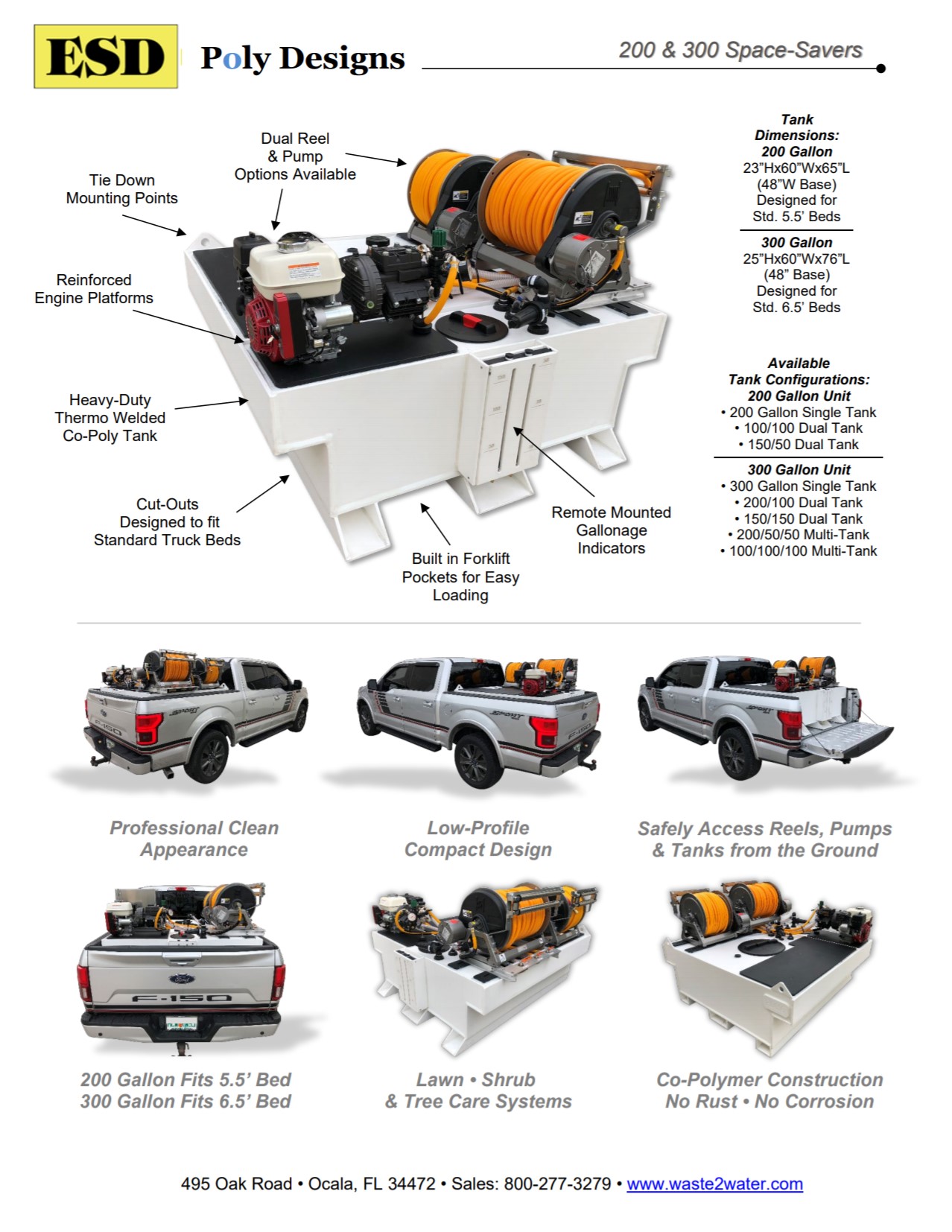

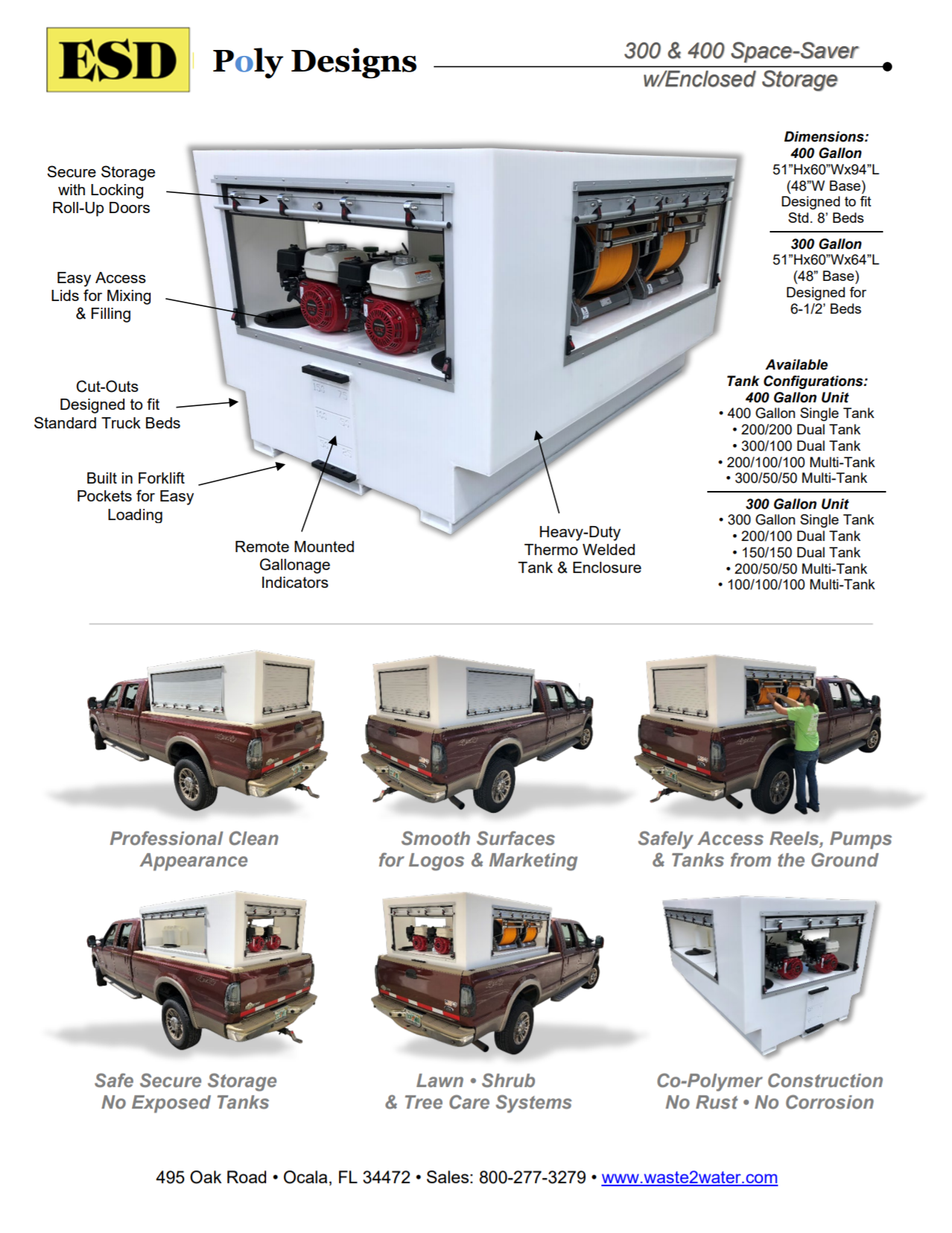

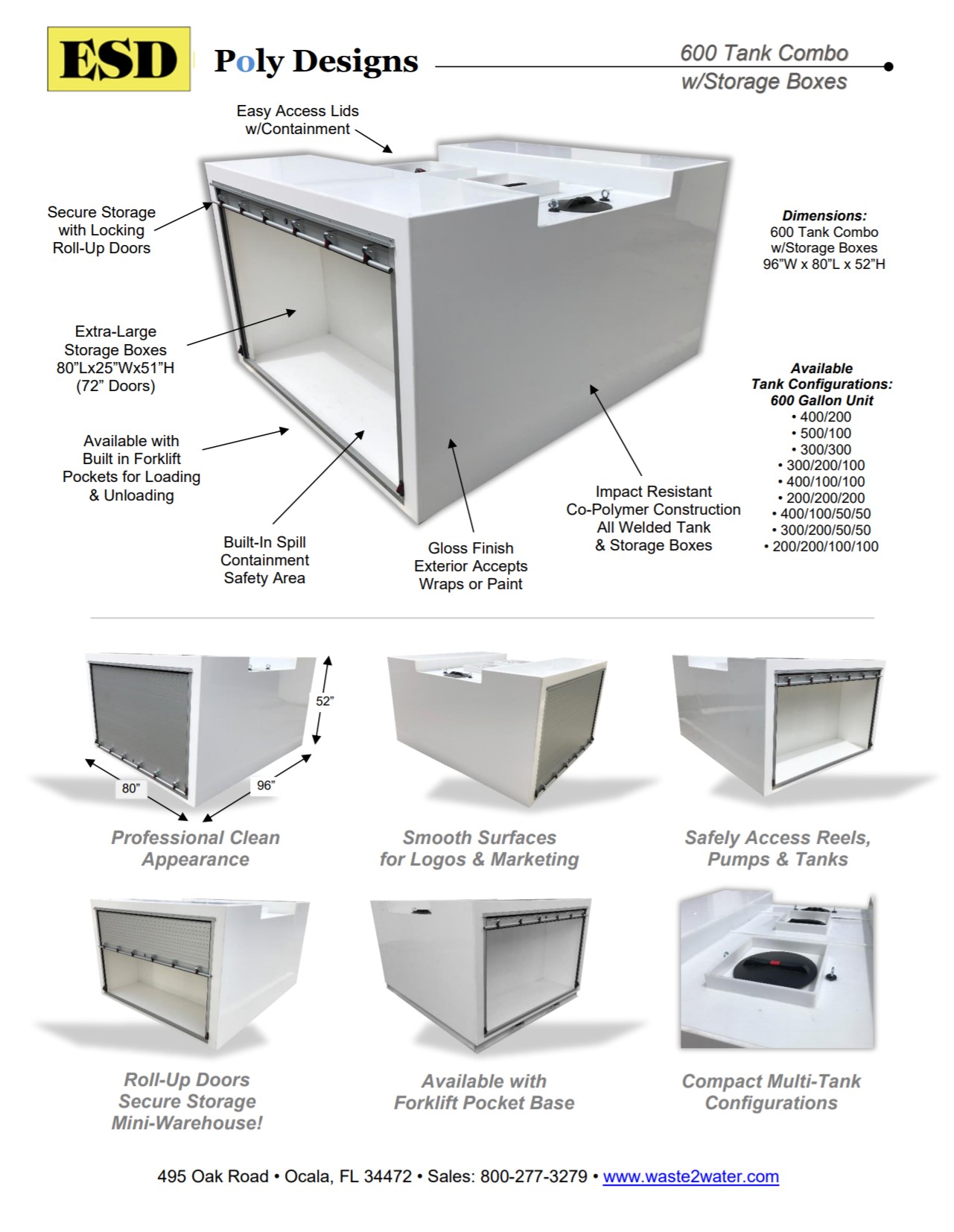

Polypropylene tanks are made from polypropylene sheet material. The manufacture of polypropylene tanks must strike a balance between prioritizing space in the truck — which would require making the tanks smaller — and prioritizing the tank’s volume capacity, which would require making the tanks bigger. For wildland fire trucks, manufacturers must also use stiffer plastic or incorporate spring mounts to make the tanks more rugged and able to stand up to a wildfire-fighting environment.

Polypropylene tank manufacturing uses the following tools:

- CNC and CAD: Polypropylene tank manufacturers use computer numerical control (CNC) and computer-assisted drawing (CAD) machines. These two technologies allow engineers and fabricators to be precise, detailed and rigorous in creating the tanks. CAD helps engineers develop minutely detailed product plans, and CNC uses coded instructions to manufacture and even 3D-print materials to precise specifications.

- Baffle construction: Most tank manufacturers use baffle designs for security reasons. When a fire truck is driving with a partially empty tank, it’s dangerous for the water to slosh around. The excessive motion of thousands of gallons of water could easily throw the truck off balance and compromise its braking and handling. It could also cause the truck to roll over. A baffle system helps solve this problem. The long, flat baffles attach to the sides of the tank to prevent sloshing and keep both tank and truck stable.

- Extrusion welding: The polypropylene sheet material is extrusion-welded together to form a light, sturdy, leakproof tank.

- NFPA Standards: All ESD Poly Tanks are fabricated to the latest NFPA standards.