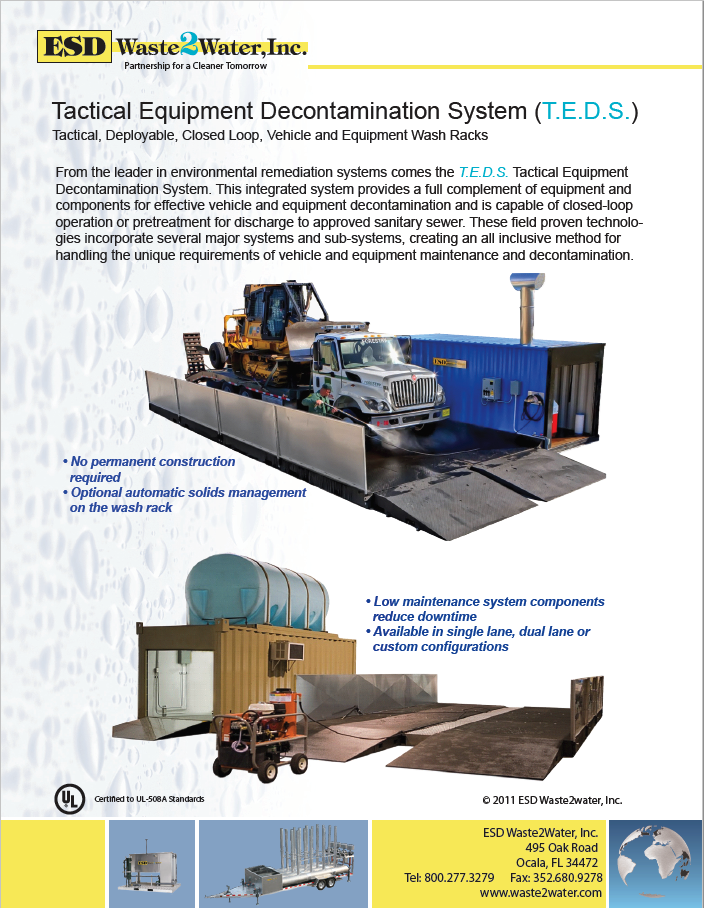

Tactical Equipment Decontamination System

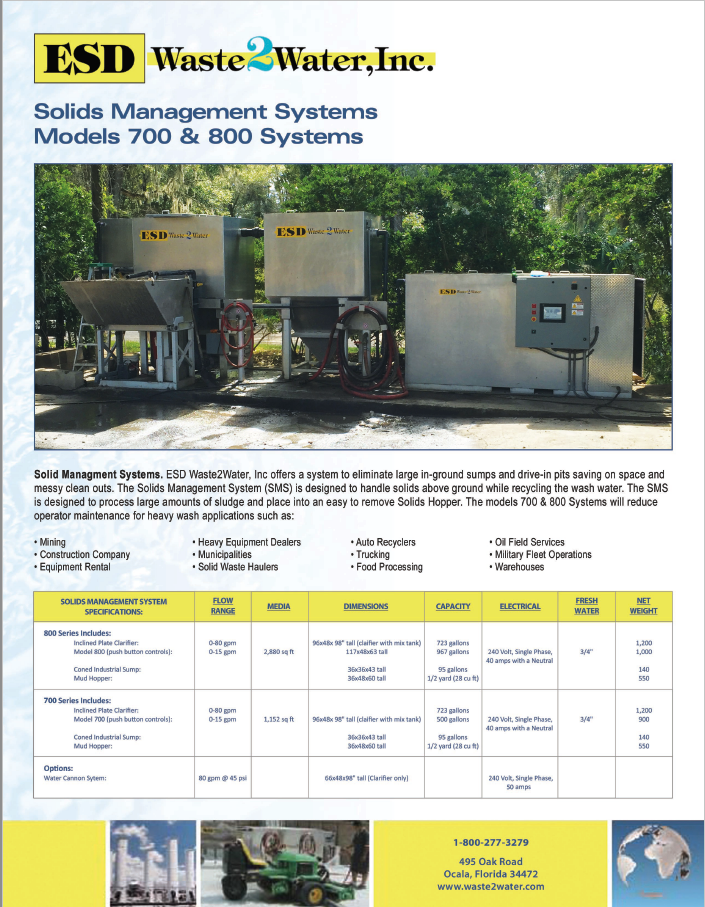

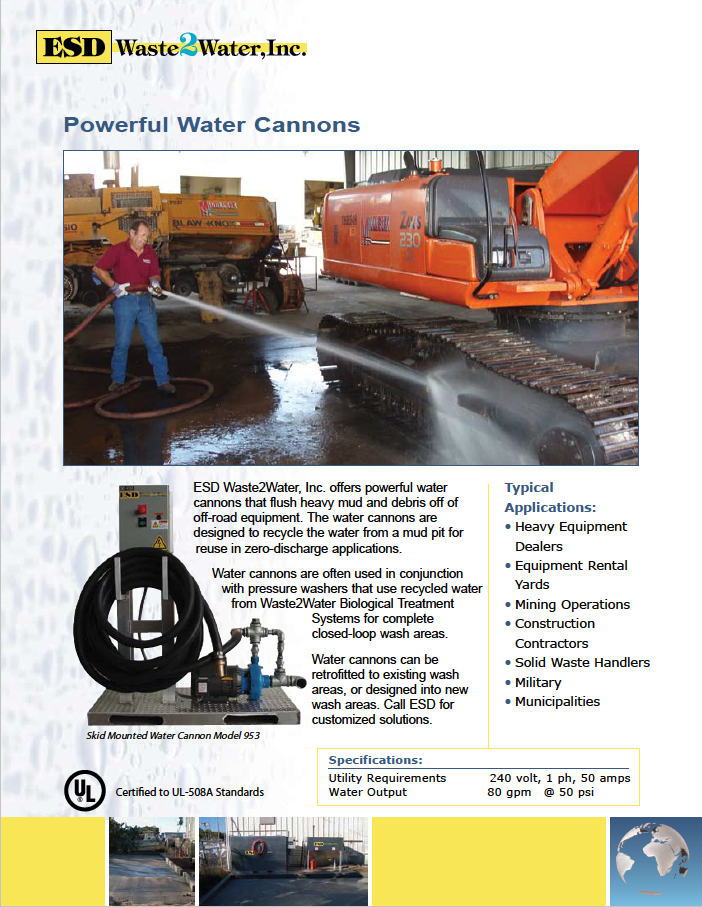

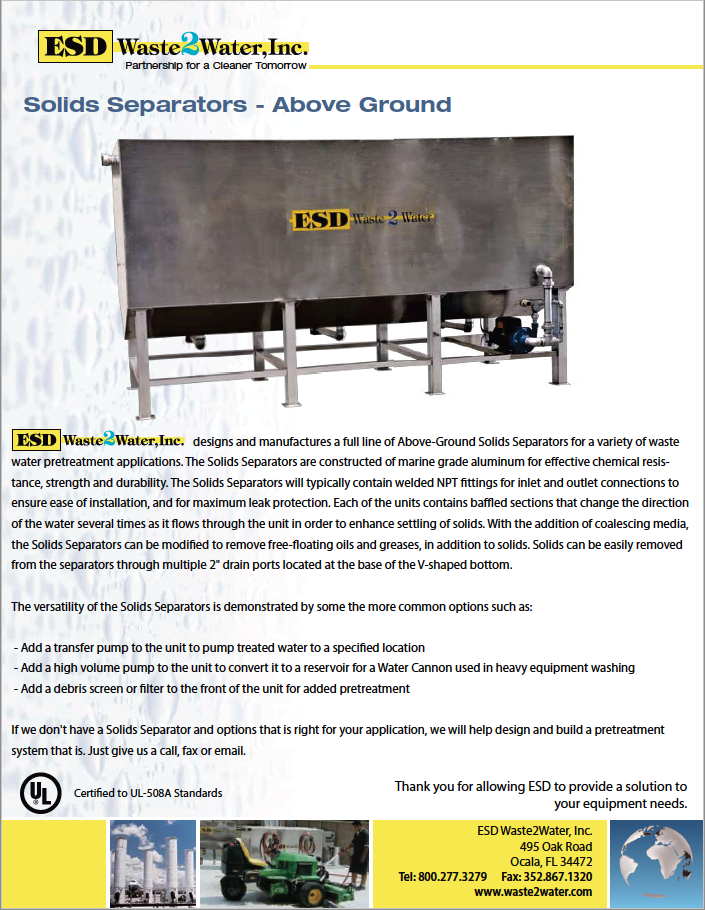

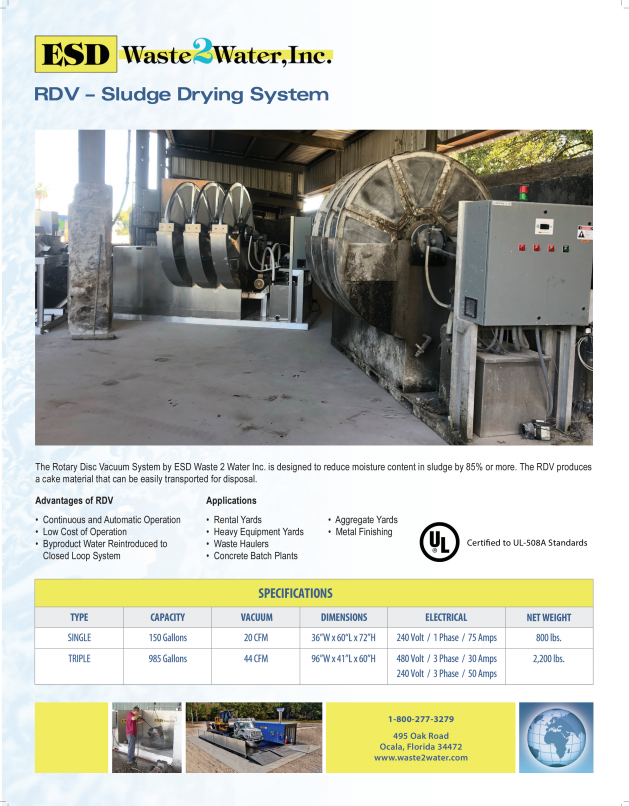

This integrated system provides a full complement of equipment and

components for effective vehicle and equipment decontamination and is capable of closed-loop

operation or pretreatment for discharge to approved sanitary sewer. These field-proven technologies incorporate several major systems and sub-systems, creating an all-inclusive method for handling the unique requirements of vehicle and equipment maintenance and decontamination.

The Mobile Decontamination & Wash Station is a self-contained wash bay with a closed loop wash system with (1) high pressure, hot water hose station for efficient and environmentally friendly washing.

The portable equipment enclosure includes all plumbing, pumps, electrical connections, lighting, and HVAC to operate as a complete wash station delivery unit.

Abbreviated System and Component Specifications:

Hot Pressure Washer:

5 gpm @ 3,000 psi, 10 hp, 230 volts, 3 phase, oil fired 440,000 btu Remote control with on/off and separate adjustable soap application Retractable hose reels for high-pressure wand and soap applicator

Wash Water Recycle System:

Biological treatment process for removing emulsified oils and greases, hydrocarbons and other organic contaminants – no chemicals added

Portable Wash Pad:

Above-ground pad system, all steel construction with 8’ modules for expansion (or shortening). Usable pad dimension 14’ wide x 40’ long. 30-ton per axle load capacity. This makes the perfect heavy equipment wash pad.

Portable Equipment Enclosure:

Environmentally controlled with equipment enclosure to include all water treatment equipment, pressure washer, and associated equipment with all plumbing, pumps, electrical connections, lighting, and HVAC to operate as a complete wash station delivery unit. The equipment enclosure is thermally insulated on all sides and includes steel beam, stainless steel, and aluminum construction. The building complies with the “International Convention for Safe Containers”-CFC.

The container can be transported by standard truck trailer, lifted by a forklift or ocean cargo handling equipment or sling lifted by a crane.

System Includes:

- A heavy equipment wash pad

- A solids separator

- A hot water pressure washer enclosed in a 40′ long equipment container.